BIM – renovation of Studio SCAI TECH – use of parametric families for various components for environmentally sustainable construction

21 March 2025Until the advent of FDM 3D printing, engineers and architects created computer simulations and renderings to design their buildings. The visualization of the latter was done through scale models made of wood or foam boards. Today, with 3D printing, and particularly with FDM (Fused Deposition Modeling) technologies, the precision of simulations and the tangibility of scale models are achieved. FDM 3D printing is a 3D printing process based on "material extrusion." A thermoplastic filament from a spool passes through an extruder that heats, melts, and extrudes the plastic through a thin nozzle.

The advantages of creating architectural prototypes in 3D:

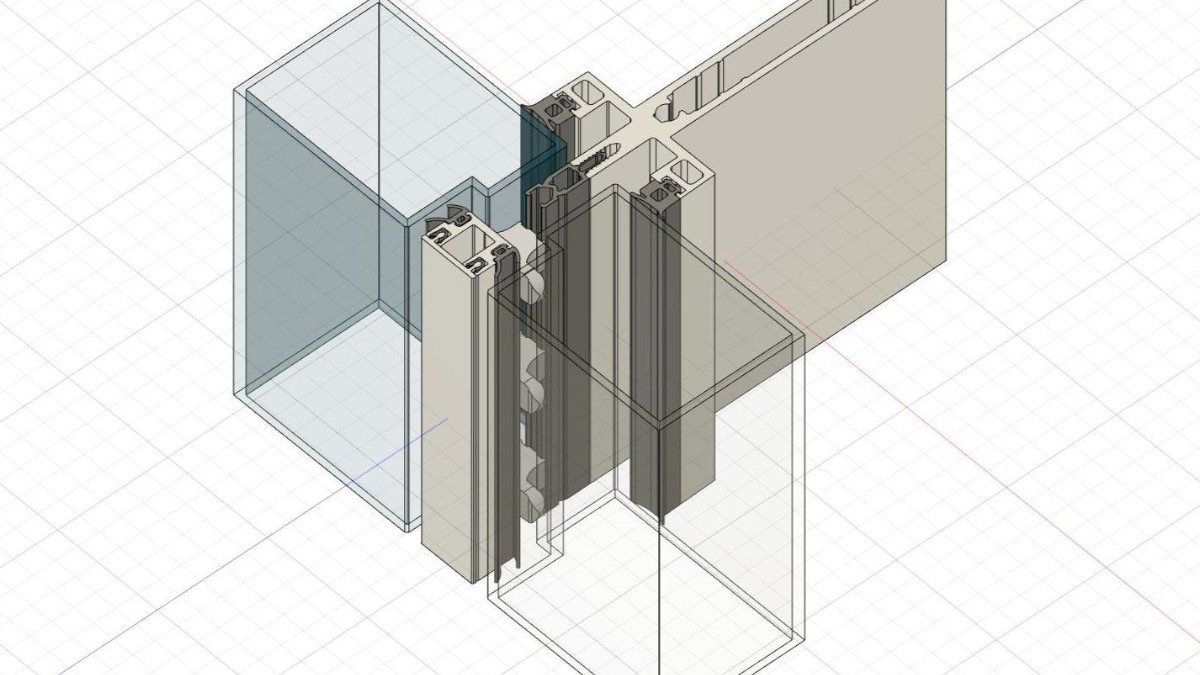

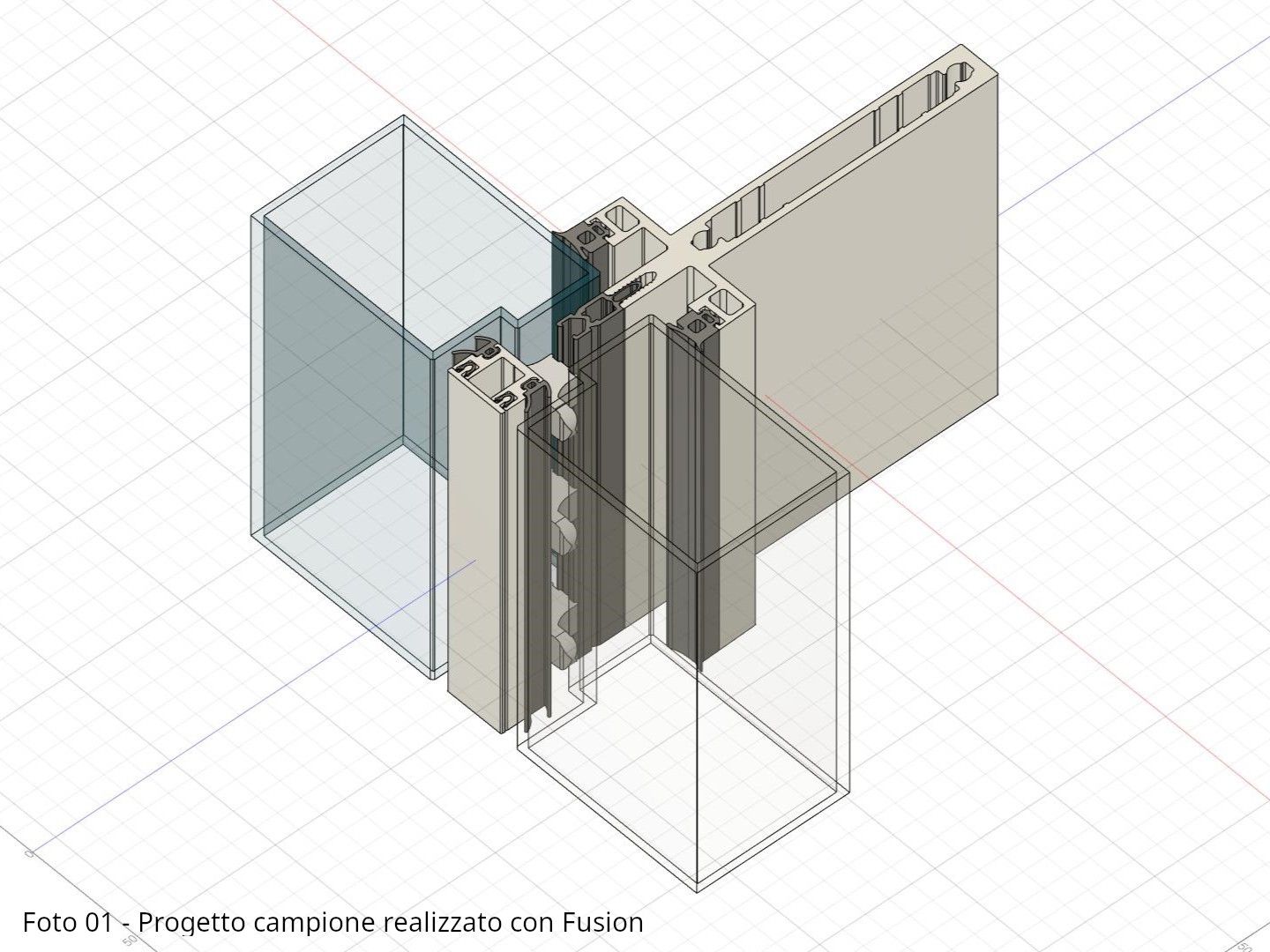

- Rapid sampling and design modifications (Photo 01)

Assistance in choosing the materials and colors for the final project or object (Photo 02)

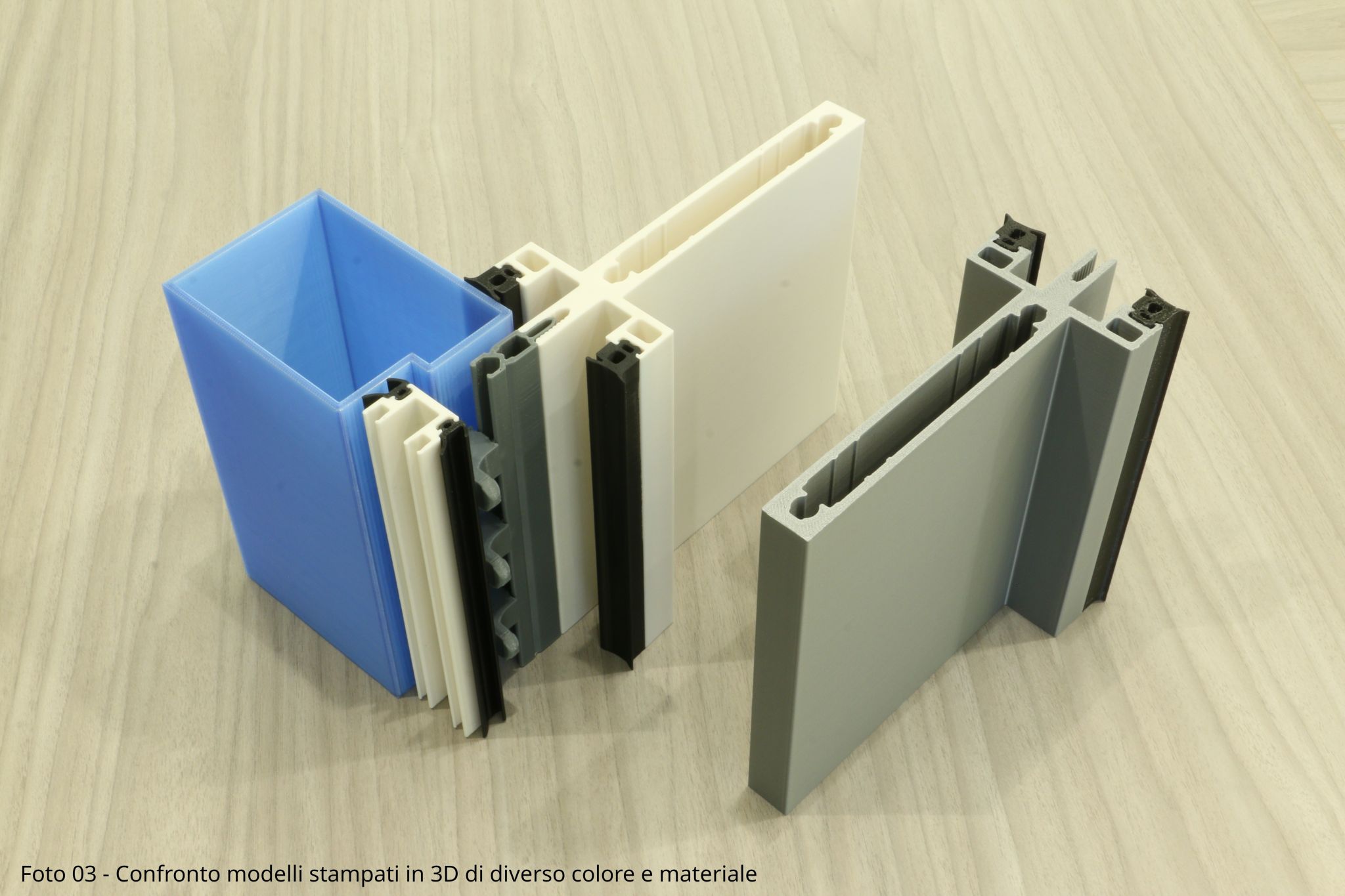

In the case of multi-component prototypes, help in selecting accessories or detailed elements (Photo 03)

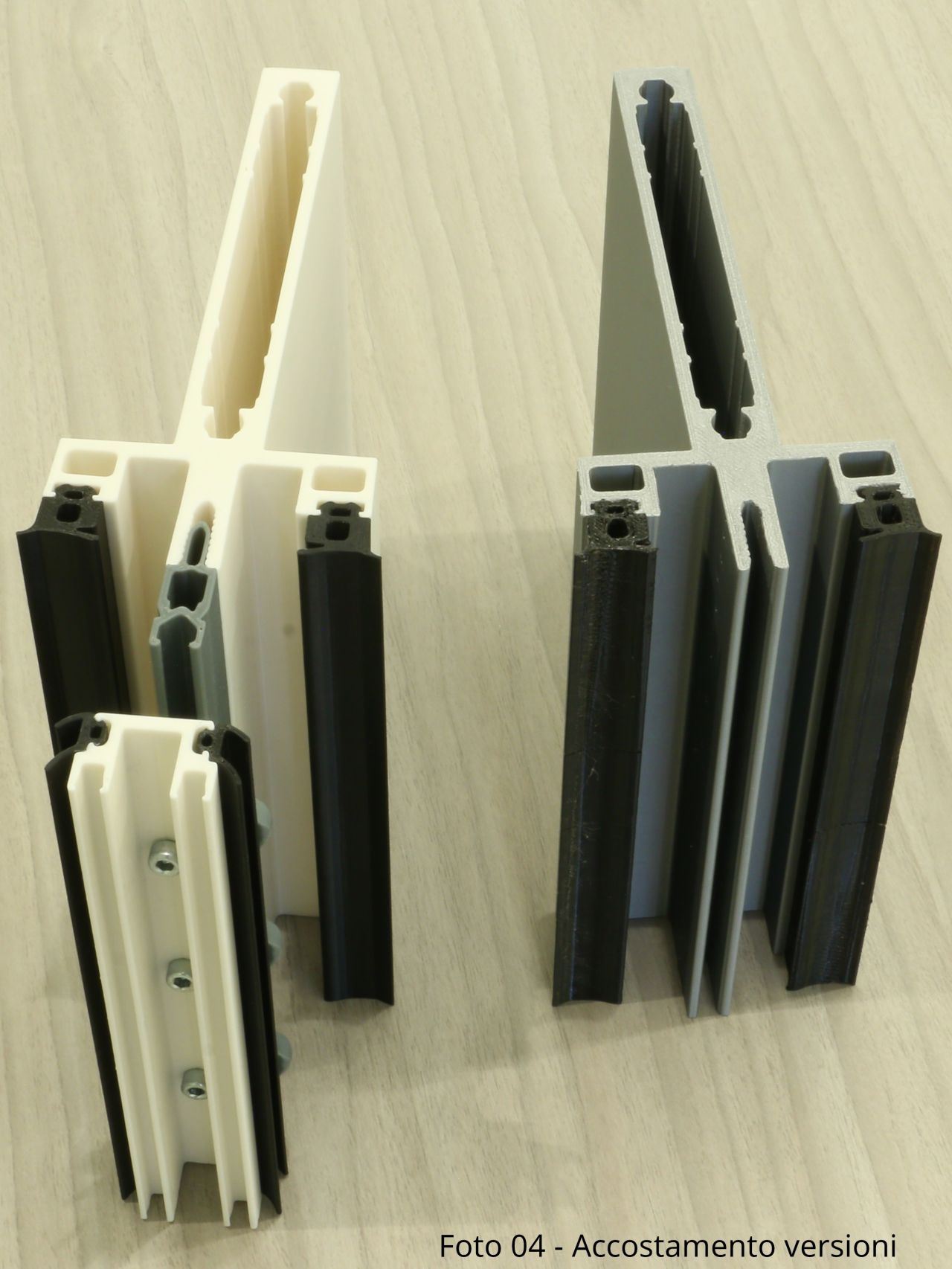

By using specific materials, the technical characteristics of the finished object can be simulated (Photo 04)

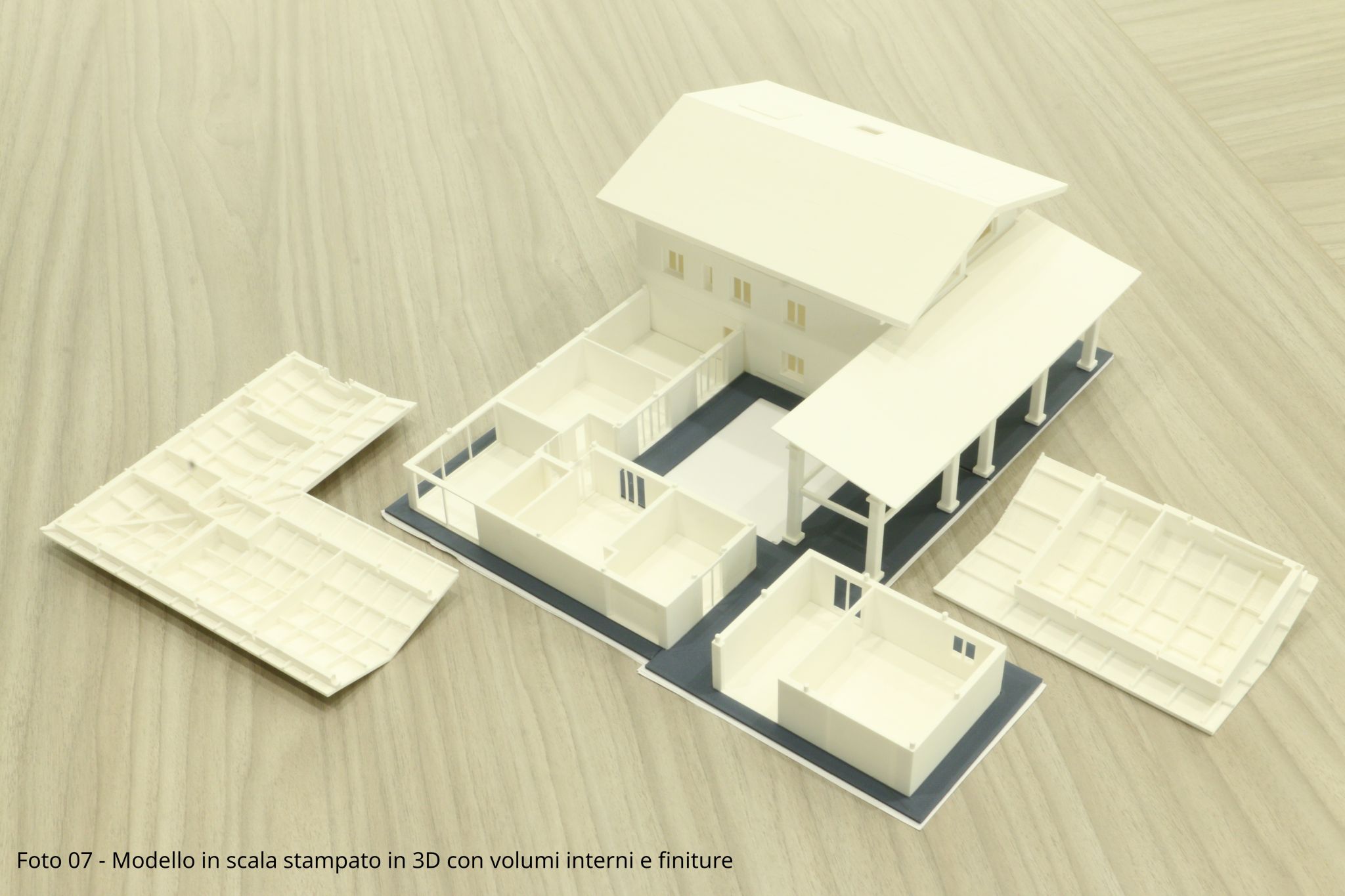

Great help in the decision-making phase to allow the client to visualize their idea before incurring more significant costs, especially in the construction of entire buildings, by verifying the final effects of the project (Photos 05-06-07)

With the increasingly rapid technological development of these machines, our studio, through the designer Dario Cattivelli, has the ability not only to create these 3D models but also to range into the creation of objects of different sizes. This extends from the smallest and most detailed prototype of a facade section to the most articulated and modular architectural scale model. This is achieved by dividing the model into multiple parts, which are then assembled using pre-configured joints or epoxy glues. We also offer a wide range of materials, from the more aesthetic ones like PLA (Polylactic Acid) and PETG (Polyethylene Terephthalate Glycol), with countless choices of colors and finishes, to very resistant technical materials like ABS/ASA (Acrylonitrile Butadiene Styrene) and flexible materials like TPU (Thermoplastic Polyurethane). It is also worth noting the possibility of printing with highly advanced materials such as carbon or glass fiber reinforced nylons (PA6-CF, PA6-GF) for the most advanced models with mechanical functions.

SCAI TECH offers to create models and prototypes at the client's request, which are obtained from an initial design with advanced programs like Autodesk Fusion and Autodesk Inventor, followed by the printing of the finished product on our machines in a short timeframe, contributing significantly to decisions in the design phase.